Category: Safety News & Information (English)

What Employees Should Know About COVID-19 Protections in the Workplace

SARS-CoV-2, the virus that causes COVID-19, spreads mostly among unvaccinated people who are in close proximity to each other. The virus spreads particularly indoors and especially in poorly ventilated areas.

Vaccination is an essential element in a multifaceted approach to protect workers. If your employer offers opportunities to take time off in order to get vaccinated, take advantage of the time offered. Vaccines authorized by the U.S Food and Drug Administration (FDA) are effective at protecting those vaccinated against symptomatic and severe cases of COVID-19 and death. A growing body of evidence suggests that those fully vaccinated are less likely to have symptomatic infection or transmit the virus, according to the Centers for Disease Control and Prevention (CDC).

Many employers have created COVID-19 prevention programs that include precautions to keep unvaccinated or otherwise at-risk employees safe. Created prevention programs might include:

- Telework

- Flexible schedules

- Engineering controls (especially ventilation)

- Administration policies (e.g. vaccination policies)

- PPE

- Face coverings

- Physical distancing

- Enhanced cleaning programs, focusing on high-touch surfaces

The recommended precautions and policies of your workplace should be followed. These multi-layered controls are specific to your workplace and are particularly important to unvaccinated or otherwise at-risk employees.

In addition to these guidelines, the CDC now recommends those that are fully vaccinated wear a mask in public indoor settings where there is a potential of substantial or high transmission. Still, those fully vaccinated might choose to mask, regardless the level of transmission. This choice might depend on if they or someone in their household is immunocompromised or at an increased risk of severe disease, or if others in their household are unvaccinated.

Ask your employer about prevention policies and plans for your workplace. Additionally, employees with disabilities who are at risk may request reasonable accommodation under the Americans with Disabilities Act (ADA).

If your employer does not have a COVID-19 prevention plan and you are unvaccinated or otherwise at risk, you can help protect yourself and others by following the steps below:

- Get a COVID-19 vaccine as soon as you can. Check with your employer about paid leave opportunities, if necessary, to get vaccinated and for recovery time from any side effects.

- Wear a face covering. When properly worn, face coverings are simple barriers worn over the mouth, nose, and chin. These coverings help prevent your respiratory droplets or large particles from reaching others. Higher quality masks are encouraged, as they provide a greater measure of protection. When working outdoors, you may opt to not wear a face covering; however, should you choose to, your employer should support you in safely wearing a face covering continuously, especially if you work closely with others.

- Social Distance. Unless fully vaccinated or not otherwise at-risk, stay far enough away from others that you are not breathing in respiratory particles produced by them. This distance is generally 6 feet (about 2 arm lengths). Please note that this is not a guarantee that you will avoid infection, especially if you are in enclosed or poorly ventilated areas.

- Take advantage of telework or flexible schedule policies, if offered by your employer.

- Perform work tasks, hold meetings, and take breaks outdoors when possible.

- Participate in any training offered by your employer to learn how rooms in your workplace are ventilated effectively, if offered. Encourage your employer to provide such training if it does not already exist. If you see any vents that are clogged, dirty, or blocked by furniture or equipment, notify your building manager.

- Practice good personal hygiene and wash your hands often. When you cough or sneeze, cover your mouth and nose with a tissue or the inside of your elbow. Do not spit. Monitor your health daily and check for COVID-19 symptoms (fever, cough, shortness of breath, etc.)

- Get tested regularly, especially if you live in areas of substantial or high community transmission.

COVID-19 vaccines are safe and highly effective at preventing you from getting COVID-19. If you are not yet fully vaccinated or otherwise at-risk, these multi-layered controls provide optimum protections that prevent exposure and infection.

Most of us have at least a rudimentary understanding of what to do if we find ourselves face-to-face with a flame in our daily lives. At least, we assume we do. So we run for the fire extinguisher, right?

The fact is, depending on the setting, the intensity of the fire, and its source, the proper method for handling a fire is different. At what point do you call emergency services? When do you pull the fire alarm? Should you use the fire extinguisher? Is there a fire suppression system? Is it working? Do you need to disable any equipment?

A well-laid fire safety plan, along with proper and frequent training, can give your workers the answers to these important questions before an emergency where their judgment could be clouded.

Fire preparedness is an important topic and falls under the responsibility of the employer. According to OSHA 29 CFR 1910.38, your Emergency Action Plan must give your employees designated actions to follow if a fire breaks out.

These actions and general guidance for fire prevention will vary widely depending on the industry and workplace area. After all, the challenges a kitchen faces to manage grease fires are far removed from safety precautions taken in an office.

Workplace Fire Safety for Offices

Offices are typically thought of as relatively risk-free workplaces. However, offices are full of electronics, power cables, equipment, and kitchen appliances that can cause a fire seemingly out of the blue.

Office Fire Prevention

In your workplace, make a safety plan to regularly ensure that:

- The wiring and condition of computers, copiers, paper shredders, power cables, and other electronic devices are in good working order. If any damaged wiring or electrical components are found, take them out of service and replace them immediately.

- Power strips, extension cables, and outlets are in good working order and not overloaded.

- Space heaters, large printers, or other energy-heavy equipment are plugged directly into a grounded wall outlet.

- Office spaces are free of clutter for easy evacuation and avoid paper, fabric, or other flammable materials coming in close contact with electrical outlets and cables.

- Kitchen appliances are regularly cleaned and unplugged when not in use.

- Store kitchen rags, paper towels, and other flammable materials away from stoves, toasters, ovens, or other heat-generating devices.

- Test and maintain smoke alarms, sprinkler systems, and fire suppression systems regularly and document the results. Perform maintenance immediately if needed.

Fire Safety for Construction Sites

A fire prevention plan for construction sites should be thorough and detailed. After all, a typical worksite will have on-the-job hazards like flammable chemicals, electrical wiring, and welding torches and sometimes overlooked risks like heaters or cigarettes from smoke breaks.

Construction Site Fire Prevention

Your construction site fire prevention protocols should include essential guidance, such as:

- Good housekeeping practices to keep flammable chemicals and materials away from ignition sources.

- Combustible waste, like rags soaked in flammable chemicals, should be disposed of in proper metal bins

- Stacked building materials and supplies should be stored so that they do not impede the effectiveness of any installed sprinkler or fire suppression systems.

- All flammable chemicals, paints, and materials should be stored and labeled away from any risk of ignition.

- All electrical wiring, temporary or permanent, should be kept in good working order without fraying or cracks. Workers should take care to minimize load on circuits as well.

- Portable heaters should be kept away from flammable materials or sides of worker tents. To avoid ignition from tipping the heater over, they should also be appropriately guarded and secured,

- Smoking should be kept in designated areas with smoke butts managed in specially-designed receptacles.

Fire Prevention in Manufacturing and Warehouses

Manufacturing and warehouse guidance varies widely depending on the types of products you store or manufacture. After all, a facility that produces baked goods would have different concerns than manufacturing or storing flammable chemical plants.

With that thought in mind, the first step to fire prevention in this industry is to evaluate your unique needs and circumstances. If you work with dangerous or flammable chemicals, you should inform the local fire department and collaborate with them to develop your fire safety plan.

Beyond these special requirements, there are still plenty of important protocols to implement to keep your workers safe from a fire igniting in their workplace. In fact, in warehouses and manufacturing facilities, most fires are caused by electrical mishaps, hot engines from major equipment, chemical reactions, or arson.

To keep your facility safe, your fire prevention plans should include:

- A regular check of facility security procedures to prevent intentional fires from petty crime.

- Ensure that flammable materials are stored in proper containers, away from ignition sources.

- Check all wiring, circuit breakers, and transformers for overloads, faulty wires, or equipment.

- Ensure that all smoke detectors and fire suppression devices are in good working order

- Keep fire extinguishers visible and in easy to access areas. Ensure that you have the proper fire extinguisher types for each facility area’s risk. For example, you would want to make sure that the hazardous chemicals keep an extinguisher designed for chemical fires.

- Ensure that exit signs and evacuation lights properly illuminate and are easily visible.

- Make sure that all discarded trash and flammable items are not blocking exits and are correctly disposed of away from ignition sources.

How to Develop a Fire Safety Plan for Work

Your fire safety plan, just like any safety regulation at work, should be a living document. However, even if you have a plan in place, your organization should regularly revisit your safety protocols to make sure they are still relevant and consider any changes in workspace, products, or other factors.

As you develop your safety plan, it’s best to collaborate with local fire officials and check OSHA’s guidance on Fire Safety in 29 CFR Subpart E – Exit Routes and Emergency Planning. Depending on your industry and materials present, you may also find relevant fire safety information in:

OSHA 29 CFR 1910 – General Industry

- Subpart G – Occupational Health and Environmental Control

- Subpart H – Hazardous Materials

- Subpart L – Fire Protection

- Subpart N – Materials Handling and Storage

- Subpart Q – Welding, Cutting and Brazing

- Subpart R – Special Industries

- Subpart Z – Toxic and Hazardous Substances

OSHA 29 CFR 1926 – Construction

- Subpart C – General Safety and Health Provisions

- Subpart F – Fire Protection and Prevention

- Subpart H – Materials Handling, Storage, Use, and Disposal

- Subpart J – Welding and Cutting

- Subpart K – Electrical

- Subpart R

- Subpart S

- Subpart T

Every facility or workplace’s fire safety plan should be unique to that facility. It should be detailed enough to cover critical information during a fire emergency, yet simple enough that your workers will be able to recall what to do in a crisis. Most plans will cover:

- Maps and evacuation routes, which are also posted clearly throughout the facility, that include meetup points for personnel from each area

- Map of building layout that shows each fire exit clearly

- Locations of critical emergency equipment including fire extinguishers, fire alarm levers, and first aid kits

- Locations of main electrical and water controls for the facility

- Scheduled frequency of facility-wide fire drills

- Regular training and refresher training on fire emergency protocols and fire extinguisher use for all employees

- Clear guidance on what to do when fires break out, even if they are small

- Clear advice on who to contact in the event of a fire emergency and the roles each employee will play during a fire

Implementing a fire safety program involves a lot of moving parts. It’s essential to collaborate with local officials and your workplace team to ensure your plan is practical and simple to enact. Even with regular training and drills, you’ll want to make sure that your employees continue to follow good safety habits through workplace supervision and educational posters on important topics like the fire extinguisher “PASS” system.

Remember, one of the most important aspects of sound fire prevention and safety at work is training. If you have a refresher course or new employee fire training on the books, National Safety Compliance can help. Our all-in-one training courses contain everything you need to hold a successful training session, including video lessons, presentations for your lecture, and printable handouts.

Our Fire Safety Training Course is suitable for Construction and General Industry and covers vital information from OSHA Standard 29 CFR 1910 Subparts E&L. This course is available on DVD/USB, instant digital access, or self-led online training courses.

Falls are a dangerous work hazard, especially in construction. In fact, according to the CDC, in 2017 falls accounted for 366 out of 971 total construction fatalities! Fall protection for your workers is the responsibility of the employers. By understanding how falls occur, planning for your worker safety, as well as providing proper safety gear and training, you can take an active role in protecting your employees.

What is an elevated fall?

In general, a fall is defined as a slip or trip causing your body to collapse due to a quick shift in your center of gravity. There are two types of falls: same-level and elevated. Same-level falls occur when you trip and fall to the floor or against a wall but you don’t fall from one level to another. Elevated falls, however, are a fall from above or below the floor from an elevated place like a ladder, building rooftop, through a skylight, or off a scaffold.

This article will focus on preventing elevated falls in construction and will not go in-depth about single-level slips, trips, and falls.

Fall Prevention in Construction

Since falls and elevated falls are major hazards in construction, their rules on fall safety and protection are well-defined. Below is a general guide to the most frequently cited OSHA regulations for construction fall prevention.

Most Frequently Cited Fall Protection OSHA Standards

1926.501(b)(13) Fall Protection—Residential Construction

When employees are working in a residential construction environment higher than 6 feet above the ground or a lower level, they need to be protected by either a guardrail, safety net, or personal fall arrest system.

1926.501(b)(1) Fall Protection—Unprotected sides and edges

If an edge or side of a walking or working surface leads to a fall that is more than 6 feet above the ground or a lower level, you’ll need to prevent falling by using guardrails, safety nets, or personal fall arrest systems.

1926.501 (b)(10) Fall Protection—Roofing work on low-slope roofs

Each employee on the roof needs fall protection if the ground or lower level is at least 6 feet down from the roof’s edge. Depending on the job’s needs, you can choose from a guardrail, safety net, personal fall arrest system. Also permitted are combinations of warning line systems and guardrails, safety nets, personal fall arrest systems, or safety monitoring systems.

1926.501 (b)(11) Fall Protection—Steep Roof

Since a steep roof is more treacherous to work on, unprotected sides should be protected with a guardrail that features toeboards, plus a safety net or personal fall arrest system.

1926.501 (b)(4)(i) Fall Protection—Skylights

From 2011-2016, over 160 workers died after falling through a skylight or a hole in a roof. Because of this, workers should be protected by a personal fall arrest system and when possible, a cover or guardrail should be installed on the skylight.

Additional Requirements

Scaffolding

Just like with unprotected roofs and other workspace edges, if scaffolding is more than six feet above the ground, guardrails should be installed. If an employee is using a float scaffold, needle beam scaffold, or ladder jack scaffold, they should also be protected by a personal fall arrest system. This is also true if they are using a single-point or two-point adjustable suspension scaffold.

Steel erection

Steel erection in construction often perches workers in precarious positions as they erect tall and narrow structures at various heights. This makes typical fall protection techniques impractical or impossible, as anchor points can be limited. In these scenarios, fall protection is required for unprotected edges more than 15 feet above a lower level.

Controlled decking zones (CDZ) are sometimes used instead of fall protection. These areas must be no more than 90 feet wide and deep from a leading edge and feature both clear boundaries and safety deck attachments. Within the CDZ, work can be performed without guardrails, fall restraints, or other safety systems but access to the area must be strictly controlled.

Stairs & Ladders

Fixed and portable ladders both must be well-constructed and frequently inspected for safety. Fixed ladders that are longer than 20 feet must feature either a fall protection system like a self-retracting lifeline, cage, or ladder safety device or they are required to feature a landing every 30 feet.

Stairs are a common site for accidental slips and falls, so whether they are temporary or not, they must feature handrails. If the stairs are temporary, they must be properly maintained and dismantled at the end of construction work.

Training

In order for your workers to keep safety in mind and practice good fall prevention techniques, they need proper training. Employers need to train their workers to set up and utilize fall protection equipment safely and effectively, as well as how to recognize fall hazards and situations where fall protection would be required.

Fall Protection Systems

In each of the commonly cited OSHA standards and requirements, fall protection systems were heavily mentioned. These systems are crucial for protecting employees from dangerous and sometimes fatal falls when working from heights.

Personal Fall Arrest Systems (PFAS)

Personal fall arrest utilizes a fall protection harness, anchor, and connector to catch an employee in the event of a fall and keep the forces of deceleration at a safe level. These systems are secured to a sturdy structure through the anchor, with the connectors commonly consisting of shock-absorbing lanyards or self-retracting lifelines attached to a body harness that distributes the fall forces throughout the body.

Fall Restraint Systems

These systems tend to be preferred by workers yet are barely mentioned in OSHA fall protection regulations. Fall restraint systems also often use a harness and connector setup, however, these systems are meant to entirely prevent a fall instead of simply catching a worker if they slip over an edge. A fall restraint system features a lead that simply does not extend far enough for a worker to be able to fall over an edge, allowing them to work safely without fear of drops.

Safety Net Systems

Safety net systems are a passive form of fall protection often installed to prevent falls by covering a potential hazard as a barrier or in a setup that will catch a worker in the event of a fall to protect them from hitting lower surfaces.

Safety nets can also be used to catch debris from construction, like bricks, wood, nails, or tools that could injure workers or bystanders below a construction site.

Guardrail Systems

Guardrails can be either temporary or permanent and are highly regulated by OSHA both in construction and for general workplace safety. Guardrails are excellent forms of fall protection because they give a visual cue that a dangerous drop is over the edge they are featured on; they provide a physical barrier between people and the fall hazard; and they can act as fall protection in areas where a cover or wall are not feasible.

While they appear similar, guardrails should not be confused for handrails. Their difference is distinct. Guardrails are used for fall protection, while handrails are used for individuals to support themselves while navigating a stairway or surface.

To protect workers and other individuals from fall hazards, a guardrail must be strongly built with posts positioned evenly to avoid people from falling through the gaps. They must also be tall enough to avoid topples over the top and extend far enough to cover the entire edge. Finally, guardrails can be made from metal or wood, but they should be smooth and not splinter or cut skin or cause clothing snags.

How to Protect Your Workers from Elevated Falls

Elevated falls are a leading cause of death for construction employees. These deaths are almost always preventable with proper planning, equipment, and training.

Plan for safety

Before elevated work ever begins, it is the responsibility of the employer to plan for how it will be completed safely. This process should begin as early as the estimation phase, where safety equipment and tools should be considered and budgeted into the construction estimate.

Provide the right equipment

It is the employers’ responsibility to provide the right fall protection and other personal protection equipment to employees so that they can conduct their work safely. Not only must this equipment be provided, but it also must be regularly inspected for fit and quality.

Train your workers

Fall arrest systems and other protective gear are only effective if your workers understand when, how, and why to use them. Robust and frequent training in fall protection for various scenarios that your workers may encounter can help keep them safe and able to spot hazards competently while performing their duties.

Fall protection is an important part of construction site safety. Elevated falls are almost always preventable, so it’s crucial we put a spotlight on this safety topic to ensure workers can perform their duties without unnecessary risks.

Fall Protection Awareness

Consider getting involved with OSHA’s annual National Safety Stand-Down by hosting events to talk to your employees about fall hazards and reinforce safety policies. This event is also a great opportunity to allow your employees to speak directly to company management about their safety concerns in an open and constructive dialog.

If you’re interested in material for a National Safety Stand-Down refresher event or need resources to properly train your employees on the importance of fall hazard safety, NSC can help. We offer several different ways to train your employees on fall hazards and fall protection. Our training kits include everything you need to hold a successful training session, including video lessons, lecture presentations, and printable handouts.

Our Fall Protection training course is available on USB/DVD, instant digital access, or as a self-led online course.

Operating a forklift requires not only an understanding of the controls to drive the forklift and the possible hazards of the workplace surroundings. Operators also need to understand the importance of load stability. Too often operators are not provided sufficient training regarding loads and the dangers presented with operating a forklift beyond its load capacity.

Forklift Load Stability Terms and Definitions

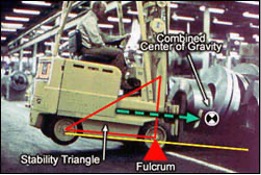

- Center of gravity – The point on an object at which all the object’s weight is concentrated. For symmetrical loads, the center of gravity is at the middle of the load.

- Fulcrum – The forklift’s axis of rotation when it tips over.

- Lateral stability – A truck’s resistance to overturning sideways.

- Line of Action – An imaginary vertical line through an object’s center of gravity.

- Load center – The horizontal distance from the load’s edge to the line of action through the load’s center of gravity.

- Longitudinal stability – The truck’s resistance to overturning forward or rearward.

- Moment – The product of the object’s weight times the distance from a fixed point (usually the fulcrum). With forklifts, the distance is measured from the point at which the truck will tip over to the object’s line of action. The distance is always measured perpendicular to the line of action. Load Moment = Weight x Distance

OSHA addresses load stability in Appendix A of the Powered Industrial Trucks Standard 29 CFR 1910.178. The stated capacity of a forklift only applies to the load center indicated on the data plate. If the load is not centered at the specified position, the forklift’s capacity will be reduced. Loads come in all shapes and sizes, not just symmetrical boxes. The load size, position, and weight distribution critically affect the forklift’s capacity and the stability of the truck.

Determining a forklift’s safe load capacity

The load weight, weight distribution, size, shape, and position are key factors affecting the capacity and the stability of the forklift. Forklifts are designed to carry a capacity load at a standard load center, commonly 24 inches. The forklift’s capacity is determined as if the load were a cube whose weight is evenly distributed, and which is resting on a standard pallet having dimensions of 48 inches by 48 inches. With such a load, the horizontal distance from the center of the load to the vertical part of the forks would be 24 inches. But most loads are not perfectly shaped cubes having their center of gravity exactly in the middle of the cube. Capacity may be reduced with irregularly shaped loads, unbalanced weight distribution, or if the load is not centered on the forks.

Understanding forklift capacity by load weight and load center distance

How weight is distributed changes the amount of weight the forklift can safely carry. This can be seen in the following experiment. An object that weights approximately 5lbs is lifted. This is the same as the forklift lifting an object.

The object is extended straight out away from the body. As it is, the center of the object’s weight moves farther from the body causing the object to feel heavier and causing a fall forward.

The same principle – increasing the load center distance – can cause a forklift to tip over. When the load center distance increases, it is increasing something called the load moment.

Whether an object is stable depends on the object’s moment at one end of a system being greater than, equal to, or smaller than the object’s moment at the system’s other end. This principle can be seen in the way a teeter-totter works. If the product of the load and distance from the fulcrum (moment) is equal to the moment at the device’s other end, the device is balanced, and it will not move. However, if there is a greater moment at one end of the device, the device will try to move downward at the end with the greater moment.

Since the overturning force depends on both the weight of the load and the load’s distance from the pivot point, a forklift’s capacity is always stated in terms of both: the load’s weight and its load center distance. Minimizing the load center distance, measured from the back of the forks to the center of the load, allows the forklift to carry more weight.

How to prevent forklift tipovers and instability

It is important to understand why forklifts tipover and loads become unstable and fall. Two factors that affect a forklift’s balance are the center of gravity and shifting center of gravity.

Center of gravity

Distribute weight evenly when carrying irregular loads and keep the center of gravity of the load as near as possible to the center going horizontally across the forks. Keeping the center of gravity of the load as near the front wheels as possible will reduce the risk of goods and equipment being damaged.

Shifting center of gravity

When the load is placed on the forklift, the combined center of gravity of the forklift and the load will move forward, but the forklift will not tipover so long as the weight of the load is centered and does not exceed the capacity stated on the data plate. But if the load is too heavy, or if it is placed at the end of the forks so that the load center distance is increased, the excessive load moment will cause the forklift to tip forward. Remember, when the forklift engages a load, the combined center of gravity of both the load and the truck system shifts forward from the center of gravity of the unloaded forklift.

Explanation of the forklift stability triangle

Almost all counterbalanced powered industrial trucks have a three-point suspension system meaning the forklift is supported at three points. This is true even if the forklift has four wheels. The truck’s steer axle is attached to the truck by a pivot pin in the axle’s center. When this point is connected to the front wheels with imaginary lines, this three-point support forms a triangle called the stability triangle.

Take a look at this diagram. In the center of the truck is Triangle ABC, where Point A is the pivot point in the rear axle and Points B and C are the front wheels. Remember that the center of gravity on the forklift will change depending on the load or momentum. If the center of gravity ends up outside the triangle, the forklift will tipover.

Let’s look at the center of gravity. An unloaded forklift’s center of gravity is between the axle of the steer wheels at A and the drive wheels at B-C. When the forklift is unloaded, the location of the center of gravity is the only factor for determining stability.

When the forklift is in motion without a load, the center of gravity is near the rear of the vehicle and very close to the side of the stability triangle, so a quick turn or unstable driving surface could cause the forklift to tip over. Be careful!

Here we see that a shift of the center of gravity occurs as the forklift is loaded. The combined center of gravity of the forklift and its maximum load shifts toward the load, so that it is now located on the line representing the front axle at the edge of the stability triangle. While the loaded forklift is theoretically still stable, in practice the combined center of gravity shouldn’t reach this line because sudden stops, starts, and turns could shift the center of gravity further out and destabilize the forklift.

When a forklift is loaded properly, it becomes more stable. However, improper loading, such as loading the forklift beyond its capacity, or loading an oversize or wide load without adjusting the weight, will cause the forklift to tipover. The direction of the tipover will depend on where the combined center of gravity shifts outside the stability triangle.

The combined center of gravity of the forklift and its maximum load shifts forward toward the load so that it is now located on the line representing the front axle, at the very edge of the stability triangle. While the loaded forklift is still theoretically stable, in practice the combined center of gravity should never reach this line because sudden stops, starts, and turns could shift the center of gravity further out and destabilize the truck, creating a forklift safety hazard to the operator and area workers..

Through the forklift’s center of gravity is a vertical line of stability or line of action. If the line of action shifts outside the stability triangle, the forklift will tip over. The placement of the load on the forks, how high the load is raised, the angle of the floor underneath the forklift, and momentum are all factors in keeping the line of action within the stability triangle.

Safe Practices for Forklift Loading and Balance

- Never exceed the stated capacity shown on the forklift’s data plate. If the load is oversized, irregularly shaped, or loaded incorrectly, the actual load center distance could exceed the stated load center distance, causing the truck’s capacity to be exceeded.

- Position the load as close to the front wheels as possible to minimize the load center distance and load the heaviest part toward the mast.

- Use extra caution and drive slower when handling extra heavy loads that may approach the truck’s maximum capacity. When handling a maximum load, the load should be carried at the lowest position possible, the truck should be accelerated slowly and evenly, and the forks should be tilted forward cautiously.

- If your forklift begins to tip, do not jump. You could be crushed beneath the forklift or load. Brace yourself, hold onto the steering wheel and pull yourself tight up to it. Keep all parts of your body inside the operator area.

Providing your workers with a solid understanding of the forklift stability triangle and best practices for load balance can help keep them save from accidents and tipovers. It is crucial for load balance to be understood and practiced while training or refreshing your operators. Training your employees on forklift safety and operation takes careful planning for your in-classroom and on-the-job training. If you’re planning a course on forklift safety, NSC makes it easy.

For our Forklift Safety Training Kits on DVD, USB, or Digital Access visit: https://www.osha-safety-training.net/product-category/topic/subject-forklift-safety/

For our Forklift Safety Training via online LMS visit: https://www.onlineoshatraining.net/product/forklift-safety-training-general-industry/

Slip and fall dangers are present in every workplace. When drafting your safety plans and protocols for most settings, it’s easy to focus on the more dramatic and dangerous hazards like fire safety, emergency training, or first aid. However, slips, trips, and falls are the second most common cause of injury at work. Shockingly, about 20-30% of people who experience a fall at work will suffer a moderate to severe injury, like deep bruising, a bone fracture, or a concussion.

Slips, trips, and fall hazards are sometimes easy to overlook because they tend to pop up unexpectedly. To maintain a safe workplace and protect your workers from preventable fall-related injuries, your safety plan should include strong protocols for footwear, signage, and housekeeping with training guidance and enforcement policies that instill safe attitudes and compliance within your employees.

OSHA Guidelines on Slips Trips and Falls

OSHA doesn’t have a set regulation about slips, trips, and falls, specifically. Instead, the bulk of the guidelines for this issue are contained in 29 CFR 1910 Subpart D Walking-Working Surfaces. This section of the Code of Federal Regulation covers both same-level falls and elevated falls, though, for this article, we will focus on same-level falls.

This important guidance went through a major overhaul in 2017 to better protect workers from hazards by adding important inspection requirements, clarifying standards, and aligning the guidance from 29 CFR 1910 General Industry with 29 CFR 1926 Construction as much as possible.

Another regulation that applies to slips, trips, and falls is 29 CFR 1910.36 and 37 Means of Egress which covers exit route safety. This standard outlines guardrail requirements, the importance of level walkways, and ice removal from exits to prevent slips.

Hazard Definitions

When we walk, our center of gravity shifts from side-to-side as we transfer our weight. With every step, there is a brief moment where our body is off-balance. When we encounter a slip or trip hazard at this moment, it can lead to a sudden fall.

Slips and trips both lead to falls. However, the difference between a slip and a trip hazard is specific and well-defined.

Slips

A slip occurs when there is too little traction between your foot and the surface that can cause a sudden loss of balance and potential fall. Slips occur on wet or oily surfaces, floors covered in fine dust or powder, or on ice.

Trips

A trip occurs when your foot or leg comes in contact with a hazard while walking. The momentum from the upper body continues to move while the tripped leg stays stationary for a moment, causing your body to fall. Trips can also occur when a person steps up or down and the surface is uneven or not at the height they expected.

Falls

When a slip or trip causes your center of gravity to shift unexpectedly, sometimes it isn’t possible to correct before the body collapses. This is when a fall has taken place.

There are two types of falls: Same level falls and elevated falls. A same level fall is when a person falls to the floor or against an object or wall. An elevated fall is when a person falls from above or below the floor, like from a ladder, scaffold, building, or into a hole.

Trip and Fall Prevention

The best way to protect your workers from these hazards is to prevent them whenever possible. Since slip and trip hazards often appear suddenly from hazards like spills or loose cables, everyone must remain vigilant to protect one another. It is the employer’s role to provide a safe workplace for all employees, so a watchful eye must always be maintained.

Footwear

Proper footwear is of the utmost importance to prevent slips and trips. This means shoes like sandals, open-toed shoes, canvas shoes, or high heels should be avoided in workplaces that often deal with slippery or uneven surfaces. Non-slip shoes or waterproof footwear can help your workers safely navigate wet or slick surfaces easily.

In-office environments where some workers choose to wear heels or sneakers, there are still precautions to take for proper footwear. Check for uneven surfaces or rugs that may snag a high heel and be sure to encourage that all employees keep their shoes snugly tied.

Signage

When a trip hazard or spill is present, signage is a great way to bring awareness to the new hazard. The trouble is many companies tend to leave their spill signs up far after the hazard is resolved or store it where it becomes part of the daily scenery.

When a sign is seen frequently, it becomes visual noise to your employees. It’s best practice to only put these signs out during the moment of danger and remove it as soon as the hazard is resolved.

Clean up spills and keep floors dry

Some of the most common causes of slips are workplace spills and wet floors. Whether the surface is wet from an accident or freshly mopped, always put out a sign as soon as possible to navigate your workers away from the wet surface. If there was a spill, it’s crucial to clean it up as soon as possible.

In wet environments like kitchens, it’s best practice to put down something to improve traction like anti-skid tape or slip-resistant mats.

Housekeeping

Anything in a walking path that could catch a foot or cause a loss of traction is a potential slip or trip hazard. Cables across walkways, paper on the floor, boxes, or hoses can all cause a dangerous accident. Items should never be left on the floor and it is important for employers to continuously check for hazardous clutter.

Encourage frequent cleaning of all work areas, including a company culture that closes drawers, puts boxes away, and hides cables in protective covers if they must extend into walking areas.

Proper lighting

Especially when navigating uneven or wet surfaces, your employees need their workplaces to be well lit to avoid falls. If they can’t see the dangers around them, how can they be expected to avoid them? Adequate lighting is required not only on the work floor, but anywhere your employees are expected to walk including stairs, halls, ramps, and exits.

Plans and protocols

Each of these methods of prevention should be written in your safety plan as company protocol that each worker has easy access to. For your slips, trips, and falls safety plan to work well, each employee must maintain a safe attitude during their daily work and act on resolving any slip or trip hazards in their area.

Importance of slips, trips, and falls training

Proper training for hazard awareness is the most effective way to avoid slip or trip injuries. Any safety orientation training or refresher course should include a reminder of the types of slip or trip hazards your workers may encounter at your facility, as well as how to safely navigate them.

Creating a culture of safety can help each worker feel comfortable pointing out a potential hazard and act on protocols to prevent injuries or incidents without hesitation. Help your workers recognize these hazards confidently with clear and frequent training. If incidents in your facility do occur, reevaluate your safety plan after you conduct an incident investigation to find methods to improve your implementation of crucial slip, trip, and fall prevention.

Ready to prevent slips, trips, and falls in your workplace? NSC makes training easy.

Our all-in-one video training kit on Slips, Trips, and Falls are available for General Industry or Construction and come with everything you need to train your employees.

To most, HIPAA compliance boils down to a simple concept: the security of patient medical information and data. With these guidelines in place, patients expect their medical data will remain private and protected from prying eyes or theft. It is your responsibility, if your company works with protected patient information, to ensure that your employees are properly implementing HIPAA compliant procedures.

A lot goes into designing HIPAA compliance training. While training should be tailored to the individual jobs at hand, there is plenty about HIPAA that every relevant worker should know. If you’re planning a class and need a simple to use HIPAA training kit with an instruction video, lesson plan, PowerPoint Presentation and certification test: we’ve got you covered.

What is HIPAA?

The Health Insurance Portability and Accountability Act, or HIPAA, is a federal law designed to protect patient health information from being disclosed without the patient’s consent or knowledge. HIPAA encompasses not only the original act but several subsequent legislative acts and together they form a vast number of regulatory requirements for a variety of entities.

What industries require HIPAA training?

The simple answer is that HIPAA regulations will apply to Covered Entities and their Business Associates. Basically, anyone who could possibly come in contact with protected health information should receive HIPAA training. This includes more obvious healthcare roles like doctors, nurses, medical receptionists and hospital recordkeepers. However, there are roles outside of the traditional healthcare system who also should be trained in HIPAA regulations.

What is a covered entity?

- Healthcare providers, including but not limited to clinics, hospitals, and private practices for medical, dental, psychological, chiropractic, etc.

- Health insurance providers, including but not limited to health insurance companies, HMOs, company healthcare plans, Medicare and Medicaid.

- This section also includes the staff that handles the sign-up process for employees or students at their company for health plans—oftentimes, these are human resources professionals.

- Healthcare Clearing House

What is a business associate?

Covered entities often work with vendors or subcontractors to handle important tasks like data storage, networking or other information technology services. Other vendors or subcontractors could include companies that provide shredding services of sensitive documents, lawyers, translation services, medical equipment professionals, answering or reception services, consultants.

With those definitions in place, let’s look at what HIPAA says about required training in the regulatory code text. The training section in the Privacy Rule states a covered entity must train all member of its workforce on the policies and procedures as necessary and appropriate. Any covered entity or business associate employee, with potential access to protected health information (PHI), must be provided regular training. The Security Rule states covered entities and business associates must implement a security awareness and training program for all members of its workforce.

What topics should be covered in HIPAA training?

HIPAA takes a somewhat vague approach to training. The law does not give specifics about required training. So, the implementation of specifics of HIPAA requirements are considered “addressable,” which simply means they must be followed but provide covered entities a level of flexibility in how they comply with the standard.

Covered entities must decide whether a given addressable implementation specification is reasonable and appropriate security measures apply within their framework. Their decisions must be documented in writing and the written documentation should include factors considered as well as the results of the risk assessment on which the decision was based.

With that documentation in place, training can be conducted with a “custom-fit” approach. It is important to train employees on many aspects of the HIPAA regulations, but the training does not have to be comprehensive on all topics. Ideally, training should be more about the company policies and procedures to ensure compliance with HIPAA law. Even so, there are some basic HIPAA components which should be covered including the following:

Important HIPAA training topics

- The HIPAA Privacy Rule

- The HIPAA Security Rule

- Patients’ Rights

- Rules on PHI disclosures

- Safeguarding electronic PHI or ePHI

- Preventing HIPAA Violations

- Breach Notifications

- Compliance and Enforcement

There are additional areas on which employees might need training. Ultimately it is up to the covered entity to determine the topics covered and make sure their employees are trained, and compliance with HIPAA is happening.

When should employees receive HIPAA training?

The Privacy Rule states that HIPAA training is required for “each new member of the workforce within a reasonable period of time after the person joins the Covered Entity’s workforce” and also when “functions are affected by a material change in policies or procedures” – again within a reasonable period of time. This implies training should occur the first few days and not months later.

How often is HIPAA training required?

According to the Security Rule, HIPAA training is required periodically. Most covered entities meet this requirement by holding annual training sessions. Annual training helps to protect the employer and employees by ensuring employees are:

- “Refreshed” on HIPAA regulations

- Aware of any policy changes that may have occurred since their last training session

- Knowledgeable about cybercrime and ways to protect against it

While annual training is sufficient to meet HIPAA’s periodic requirements, holding additional training sessions throughout the year is not a bad idea. These other sessions can be shorter and provide quick info to reinforce employee’s knowledge and compliance with HIPAA.

Tips for HIPAA compliance training

An effective HIPAA training program allows employees to participate in the training process and to practice their skills or knowledge. This will help to ensure they are learning the required knowledge or skills. Employees can become involved in the training process by participating in discussions, asking questions, contributing their knowledge and expertise, learning through hands-on experiences, and through role-playing exercises.

Steps can be taken to help ensure employees are attentive and engaged during HIPAA training.

- Keep training sessions under an hour in length. Long training sessions lose the attention of the trainees.

- Keep the employees engaged. Asking questions and encouraging conversation helps to keep employees plugged-in to the training session.

- Keep handouts to a minimum and make sure the ones you hand out are meaningful. Too many handouts will draw the employee’s attention away from what is currently being discussed.

- Include various media for different learning types, including videos, classroom presentations, quizzes and discussion.

- Make HIPAA compliance training simple

HIPAA compliance requires frequent and effective training that gives your employees the tools and knowledge they need to implement these critical guidelines in their everyday work. The best HIPAA training courses will combine interactive elements with classroom lecture and discussion to help your employees learn and implement these crucial guidelines.

Ready to train your employees? NSC makes HIPAA compliance easy. Our all-in-one HIPAA Compliance training course contains everything you need to run a successful class, including a training video developed by industry experts, classroom presentation, supplemental handouts and printable certificates. This course is available on DVD, digital access, or in a self-guided online training course.

Lockout and tagout, also known as LOTO, is the OSHA standard for the control of hazardous energy. This exists to protect employees by addressing the necessary steps to disable machinery or equipment that could release hazardous energy or unexpectedly start. These hazardous energies, including electrical, hydraulic, pneumatic, chemical, thermal, or mechanical could seriously harm or kill workers if released during machinery work or maintenance.

Lockouts and tagouts put specific practices and procedures into place to isolate machinery energy hazards by de-energizing and locking out the ability to power on the equipment.

Failure to properly follow lockout tagout regulations are one of OSHA’s top 10 most frequent citations. Not only are there fines involved when you choose not to follow regulations but there are many dangerous situations you will create for your employees and anyone in your work environment.

Lockout/tagout procedures must be taken seriously. If procedures and requirements are not met employees can be gravely injured or killed by machinery and equipment. OSHA estimates that compliance with the lockout/tagout standards can prevent 120 fatalities and 50,000 injuries every year.

Training on Proper Lockout and Tagout Procedures

Employees working on machinery are at high risk of bodily harm if someone removes lockout/tagout devices and reenergizes the equipment without their knowledge. It is extremely important that all employees respect lock out and tag out devices and that only the person who applied them may remove them.

According to OSHA’s guidelines, your lockout/tagout program must include energy control procedures, devices to lockout, inspections of lockout/tagout devices and mandated training for all employees. This training should be specific to each employee’s position and be relevant to their individual duties.

Proper training will give employees a better understanding of the types of energies that can cause danger and teach them how to implement procedures to ensure these energies are controlled during maintenance and service.

Training, and retraining regularly to maintain proficiency and protocol adherence, is crucial to the success of your Hazardous Energy Control Program.

Difference Between Lockout and Tagouts

Although the terms lockout and tagout have similar desired effects, the two devices are quite different. Lock out devices hold hazardous energy in isolation and prevent machines from being energized with physical restraints that cannot be removed without a key.

On the other end of the spectrum, tag out devices simply warn employees against reenergizing devices while it is being serviced. These are much easier to remove, and as a result, they do not provide the same level of protection as lockouts.

Lock out and tag out kits provide bundles of both that can be used for multiple procedures. They contain tags, padlocks, and all other devices to isolate energy release. These allow companies to manage all their operations from a centralized box, which makes implementing a lockout tagout program easier. Lockout programs can be tricky and having all the effective tools makes all the difference.

Standards for Lockout Tagout

The OSHA standards for The Control of Hazardous Energy (Lockout/Tagout), Title 29 Code of Federal Regulations (CFR) Part 1910.147 and 1910.333 layout the requirements for disabling machinery during maintenance work and protecting workers from electrical circuits or equipment.

You must use a lockout program (or tagout program that provides protection levels equal to that achieved through lockout) whenever your employees engage in service or maintenance. This system normally involves taking dangerous equipment completely offline and removing its ability to energize by locking it into an “off” position, then tagging it to the individual who placed the lock and who is the only person able to remove it.

The basic requirements as stated in the standards are as follows:

- Employers must draft, implement, and enforce an energy control program and procedures.

- A lockout device, which temporarily disables machinery so that hazardous energy cannot be released, must be used if the machinery supports it. Otherwise, tagout devices, which are warnings to indicate that the machinery is under maintenance and cannot be energized until the tag is removed, can be used if the employee protection program provides equal protection to a lockout program.

- Lockout/Tagout devices must be protective, substantial, and authorized for the machinery.

- All-new, refurbished, or overhauled equipment must be capable of being locked out.

- Lockout/tagout devices must identify each user and only the employee who initiated the lockout can remove it.

- Effective training must be provided to all employees who work on, around, and with heavy machinery and equipment to ensure understanding of hazardous energy control procedures including their workplace’s energy control plan, their specific position’s role and duties within that plan, and OSHA requirements for lockout/tagout.

- Training must be repeated once a year

- Inspections must be performed of energy control procedures and initiatives.

Implementing a safe and effective lockout/tagout system is ultimately a task of the employer. It is the business’ responsibility to protect their employees from injury or death by providing them the tools, standards, procedures, and training to avoid hazardous workplace accidents.

Who Needs to Utilize Lockout Tagout(LOTO) PROCEDURES?

Lockout tagout procedures and training are necessary for all companies with equipment and facilities with hazardous energy. These are necessary both to meet OSHA guidelines and keep your employees safe.

Some examples of workplaces that would require both LOTO procedures and training include:

- A distribution center that utilizes equipment like forklifts and palletizers would need a lockout/tagout procedure set in place.

- A bakery food manufacturer would need a lockout/tagout procedure for maintenance on their industrial oven and conveyor belts.

- In the printing industry, if cleaning or maintenance duties on a press must be performed under machinery guards or in hazardous points.

When moving forward with building your lockout tagout procedures, keep in mind that not all employees will use the lockouts and tagouts. Only authorized personnel, meaning those trained on a company’s lockout tagout procedure can properly understand, apply, and follow procedure.

Regardless of whether or not they are considered authorized personnel and are using the lockout/tagouts, employees will still need to be trained. Any employees who operate the machines that will be serviced under lockout tagout or work in the area where lockout tagout is used will need to understand the purpose and seriousness of lockout tagout procedures.

Steps of Lockout Tagout

The general steps of lockout/tagout application require authorized personnel to perform a sequence of shutdown and inspection procedures. To initiate the LOTO and prepare for maintenance, you must:

Step 1: Inform the Workers

Before the machinery is shut down, all employees that work on or around the machine must be informed that the energy control procedures will be applied at a specific time. If anything changes, including the maintenance time or expected downtime, inform these employees.

Step 2: Power down the machine

Based on manufacturer guidance and your shutdown procedures, have an authorized employee turn off the machine.

Step 3: Isolate energy sources

Most equipment will have more than one source of energy. Any area of the machine that could be energized by electric, hydraulic, pneumatic, chemical, thermal, or mechanical power must be shut down by powering down switches or shutting valves.

Step 4: Add the lock and tag

At all of the previously identified energy sources that can be used to re-energize the machine, apply locks and tags with identification of the authorized employee who placed them. Only the employee who placed them is allowed to remove these tags.

Step 5: Release any stored energy and prepare the area

Some machines can retain stored energy even after a shutdown. Look for hazards like spring tension or venting gases and release them appropriately. Moving parts must be safely secured to protect maintenance workers and remain stable throughout the cleaning or repairs.

Step 6: Verify that energy is isolated

Authorized personnel must now double-check and verify all previous steps were completed successfully.

Once the maintenance is complete, the LOTO must be removed. The following steps must be followed to remove the tags safely:

Step 1: Inform the workers

Communicate to all area workers that the machinery will be re-energized at a specific time. Ensure that all equipment brought in for repairs is removed before turning the machine back on and all maintenance personnel are accounted for.

Step 2: Remove the locks and tags

Authorized personnel will now remove the tags they placed earlier. Each tag can only be removed by the person who placed it.

Step 3: Re-energize the machinery

At the appointed time, re-energize the machinery.

Lockout/tagout procedures are not only important for OSHA compliance, they are vital to employee safety. To ensure your program is working as intended, annual inspections of lockout/tagout procedures are required by OSHA. While employees aren’t required to have annual refresher training, all employees must be well-trained and able to follow protocol at all times. If knowledge gaps are found, employees change work positions or if new machinery is added to the workplace, refresher training is required.

At National Safety Compliance, we offer a number of different ways to train your employees on lockout tagout safety, lockout tagout devices, and online training modules here on Online OSHA Training, as well as more traditional employer-led training programs available on DVD, USB, or Digital Access on OSHA-Safety-Training.net.

Powered industrial trucks, commonly known as forklifts, are used in a variety of industries. From manufacturing plants to warehouses to construction sites, forklifts are critical pieces of workplace equipment used to raise, lower, and move materials. With their presence being so commonplace it is no surprise how many employers are interested in understanding and providing compliant, effective training for their employees.

Forklift safety training is not only essential for a safe working environment but required under the most recent OSHA regulations. Forklifts are an exceptional tool for efficiency, but they can also be dangerous, damaging, or even deadly. According to a report from the U.S. Bureau of Labor Statistics, more than 600 workers perished in forklift accidents from 2011 to 2017, and a further 7,000 suffered injuries that required time away from work.

To start on the path towards developing forklift safety training for your team, you must first understand the OSHA regulations and how to put these rules into action.

Most Recent OSHA Regulations for Forklift Operators

The most recent OSHA regulations for forklift operators were officially published on December 1, 1998. In response to a rise in workplace safety concerns, the new standard was designed to lower workplace injuries and fatalities through quality operator training.

These new regulations went into effect on March 1, 1999 and apply to all industries except for agriculture.

The new regulations are as follows:

- Operator performance must be evaluated before operating an industrial truck, except for when in training

- The employer can designate any employee who is qualified as a Trainer or Evaluator. There are no special requirements for training.

- OSHA does not certify, accredit, or approve any trainers or training programs for powered industrial trucks. The responsibility for compliance with the requirements of the OSHA standard rests with the employer.

In summary: All employers with forklifts or powered industrial trucks outside of agricultural settings must provide OSHA-compliant training for their operators, evaluate operator performance before allowing them to operate the vehicle, and can designate any qualified employee to act as a trainer or evaluator.

Forklift Trainer Requirements Under OSHA Regulations

Under the guidance of OSHA regulations, ensuring that your forklift operators are properly trained is ultimately the responsibility of the employer. This task can be outsourced to outside consultants or pre-developed courses for the classroom portion can be utilized. However, the training provided must adequately prepare your employees for not only general forklift operation, but the unique challenges present in your specific workplace.

Forklift Training Format

Training programs must consist of a combination of formal or classroom-type instruction, using tools such as:

- Lecture formats

- Video formats

- Class discussions and games or activities

- Written materials, worksheets, or training booklets

- Online interactive training

Training must also include a practical, hands-on approach, such as:

- Demonstrations performed by the trainer

- Practical exercises performed, with supervision, by the trainees

- Evaluation of the operator’s performance in the workplace

Trainees participating in hands-on activities can only operate the vehicle as long as it does not endanger them or other employees. This means during the practical portion of training, a safe location should be secured and designated as such to minimize the presence of others in the area. The trainee must also remain supervised at all times during operation until they are certified.

Training Content

The content of the training program must consist of several topics, such as location-specific hazards and truck-specific topics. If operators are going to use different types of forklifts, they must be trained on each vehicle class or type.

Workplace-specific training

Your training plan must include hands-on and written instruction about the vehicles or workplace hazards specific to your place of business. If your business has multiple locations in which the operators will be using forklifts, they must be trained on the hazards that are unique to each of the locations.

Topics for this portion of the training must include:

- Surface conditions where the vehicle will be operated

- Composition of loads to be carried and load stability

- Load manipulation, stacking, and unstacking

- Pedestrian traffic in areas where the vehicle will be operated

- Narrow aisles and other restricted places where the vehicle will be operated

- Hazardous (classified) locations where the vehicle will be operated

- Ramps and other sloped surfaces that could affect the vehicle’s stability

- Closed environments and other areas where insufficient ventilation or poor vehicle maintenance could cause a buildup of carbon monoxide or diesel exhaust

- Other unique or potentially hazardous environmental conditions in the workplace that could affect safe operation.

Truck-related topics

Training must go beyond the basic operation of the industrial powered truck and include comprehensive information about the vehicle’s controls, capacity, maintenance, and precautions.

Topics for this portion must include:

- How to read and understand the forklift’s required name plate / data plate and find vital information such as fuel type and capacity

- Operating instructions, warnings, and precautions for the types of truck the operator will be authorized to operate

- Differences between the truck and an automobile

- Truck controls and instrumentation: where they are located, what they do, and how they work

- Engine or motor operation

- Steering and maneuvering

- Visibility (including restrictions due to loading)

- Fork and attachment adaptation, operation, and use limitations

- Vehicle stability

- Any vehicle inspection and maintenance that the operator will be required to perform

- Refueling and/or charging and recharging of batteries

- Operating limitations

- Any other operating instructions, warnings, or precautions listed in the operator’s manual for the types of vehicle that the employee is being trained to operate

Vehicle class-specific training

There are many types of forklifts used. If your business owns multiple types, operators do not need to be trained on each make and model. But, operators must receive truck-specific training on those types they will be expected to operate. Operators trained to use a sit-down type fork truck cannot operate a stand-up truck unless they have been trained to operate it.

The vehicle classes for powered industrial trucks are as follows:

Class I: Electric motor rider truck

These general use vehicles are most often found indoors, though varieties with pneumatic tires are sometimes used outdoors in dry conditions. These vehicles are versatile and protect air quality by running on battery instead of gasoline, natural gas, or diesel fuel.

Class II: Electric motor narrow aisle trucks

These narrow vehicles are designed to operate in small spaces efficiently. Narrow forklifts allow for their companies to pack in shelving or aisles close together to maximize storage area.

Class III: Electric motor hand trucks or hand rider trucks

These small vehicles battery-powered vehicles are driven by an operator in front of the truck. Steering and controls are contained in the tiller.

Class IV: Internal combustion engine trucks with solid, cushion tires

These forklifts are often seen couriering pallets from the loading dock to indoor storage. They feature a low clearance thanks to their smaller profile tires and can be used indoors or outdoors on smooth surfaces.

Class V: Internal combustion engine trucks with pneumatic tires

These trucks feature an internal combustion engine that is powered by compressed, diesel or LP gas. They are versatile and seen in all kinds of warehouses, from large to small.

Class VI: Electric and internal combustion engine tractors

These electric and combustion-powered tractors are known for their pulling power and are commonly seen on the airport tarmac hauling luggage.

Class VII: Rough terrain forklift trucks

Popular in construction, these large forklifts are designed for heavy outdoor use at a job site to lift and transport large loads of lumber or building materials.

Vehicle Inspection Training

According to OSHA guidelines, forklifts need to be inspected either daily or at the end of every shift if they’re used continuously. Before any driver begins work for the day, they must perform both a walkaround inspection and a seated inspection. In order for employees to properly perform this inspection, they must be formally trained on hazards and where to look for them.

Walkaround inspection

The walkaround inspection involves checking major areas of the vehicle, such as the tires, hoses & belts, fluids, forks, engine, and data plate for safety and good condition.

Seated inspection

The seated inspection is performed while the driver is in their seat. They must check that the controls, safety equipment, horn, brake, steering, seatbelt, and gauges are all in safe, operating condition.

Training the Trainers

OSHA’s regulation CFR 1910.178 (l) Operator Training spells out clearly what you need to do to correctly train employees to use forklifts.

While OSHA does not require special training or certification for forklift trainers or evaluators, they must be qualified for the task. Ensure that your operator training is conducted by someone who has the knowledge and experience to educate powered industrial truck operators and evaluate their competence.

In some cases, this may mean you will want to hire an outside training consultant. In many instances, however, this is not necessary. While outside trainers are certain to have the skill and expertise to train your employees, this does not mean you must hire an outside training consultant or company. Depending upon your circumstances it may be better if you do, but it is not required by OSHA. You simply must ensure that the person conducting the training “has the knowledge, training, and experience to train.”

Timing of forklift training

New operators

Operators with no certification must complete the full training program before operating a forklift. Until they are certified, they can only operate the vehicle under direct supervision while participating in the training.

New employees

Experienced operators who are new to your company and bring with them an outside certification are not necessarily required to go through the full training course. Instead, if you have reason to believe their training is sufficient, you can simply evaluate their skills and train them on only workplace-specific tasks, hazards, and vehicles.

Deficient operators

Deficient operators must go through refresher training when the following occurs:

- The operator has been observed to operate the vehicle in an unsafe manner

- The operator has been involved in an accident or near-miss incident

- The operator has received an evaluation that reveals that the operator is not operating the truck safely

- The operator is assigned to drive a different type of truck

- A condition in the workplace changes in a manner that could affect the safe operation of the truck.

To ensure that the workplace incident was not because of faulty guidance, an evaluation of the entire training program must be performed when refresher training is required.

Seasoned operators

Current OSHA regulations require an evaluation of each forklift operator’s performance at least once every three years. If the operator continues to perform safely and within the guidelines set by your training, no further classwork is required at that time.

Temporary employees

Employees that join your company through a contractor or temporary agency must still be certified to operate a forklift. Since temporary agencies are the employer of your temporary employee, not the host organization, it is the responsibility of the agency or contractor to provide training to the required standard or there must be an agreed-upon plan for providing training between your business and the agency.

If the agency is the one to provide training, your business must still train temporary employees on workplace-specific vehicles and hazards.

Minors

Under no circumstances is a minor allowed to operate a forklift. This is a violation of federal law. All operators must be over the age of 18 before beginning training.

Certification document requirements

OSHA also requires that you certify that each operator has been trained and evaluated. Many folks misunderstand this and think that training must be OSHA-certified. OSHA does not certify your training. This simply means you must document that training was provided and that the training met the requirements laid out in section (l) of the CFR 1910.178. To certify the training, you must document:

- The name of the operator

- The date of the training

- The date of the evaluation

- The identity of the person(s) performing the training or evaluating the training.

Employer training records

Records of training, performance, and certifications should be kept for at least the duration of employment.

Forklift training under OSHA guidance is one step towards creating a safer workplace for all employees. With some knowledge of OSHA’s requirements, thoughtful classroom planning, and seasoned workers with the skills to train, you will find this process is mostly straightforward. By the end of the training, you should be confident that your operators understand the training they have received and can safely operate the vehicle and have thorough documentation of the training provided.

For our Forklift Safety Training Kits on DVD, USB, or Digital Access visit: https://www.osha-safety-training.net/product-category/topic/subject-forklift-safety/

For our Forklift Safety Training via online LMS visit: https://www.onlineoshatraining.net/product/forklift-safety-training-general-industry/

What Does PPE Stand For?

Personal protective equipment (PPE) is essential for those working on the frontlines of the COVID-19 pandemic. In general, PPE protects wearers from environmental hazards that could cause injury or illness. These hazards include physical, chemical, radiological, electrical, mechanical, and biological damage. During the current coronavirus pandemic, wearing PPE significantly reduces the chance of being exposed to or spreading germs by creating a barrier between yourself and possible infectious diseases. We offer complete PPE Training Kits here at National Safety Compliance.

2020 has Seen an Unprecedented Increase in PPE Usage

While the use of PPE in all workplaces across the world is certainly spiking, PPE is nothing new for most health care workers. In the past, all hospital staff members and visitors have been required to use PPE in instances where there is potential for contact with blood or bodily fluids. Now, PPE is required around the clock in hospitals as well as other businesses and facilities across the nation to prevent the transmission of the novel coronavirus COVID-19.

For PPE to work effectively, employers must properly train their workers on how to use PPE efficiently. If PPE is something only used rarely, employees should still practice regularly putting on, properly wearing, and taking off their personal protective equipment. This proper training is a must, and employees should be refreshed on these topics on a regular basis.

With the addition of new businesses needing to implement requirements for PPE, there are also many different types of PPE to meet the needs of each industry. These can range depending on your line of business. For example, the PPE that a hospital utilizes will be much different than the PPE used in a restaurant. The different forms of PPE can include;

- Masks and Respirators: These should always cover both your mouth and nose to prevent the inhalation of germs, chemicals, and physical contaminants. Masks also play an important part in stopping asymptomatic employees from spreading disease.

- Eye protection: Some masks come with a clear plastic piece to cover your eyes, other forms of eye protection can include face shields and goggles. These are important in some settings because of how easily germs and other particles can enter through or damage one’s eyes.

- Gloves: Wearing gloves protects your hands by creating a physical barrier. It’s important to avoid touching the body or face while wearing protective gloves, and regularly change them after any possible contamination.

- Clothing: This includes much of what you would picture a surgeon wearing; gowns, aprons, head covering, and shoe covers and while they are often used during surgeries, they can also be used to visit someone who is in isolation or to keep dangerous liquids from touching your skin. Clothing can also be used in other industries outside of the medical field like chemical protective suits for cleaning, reflective vests for outdoor night workers, and lead aprons for radiological workers.

Depending on your local and state mandates, you as an employer can control how often employees are required to wear PPE in certain situations. This can depend on your risk of being severely impacted by COVID-19, but regardless of these requirements, healthcare workers always need PPE when caring for others in isolation. PPE is also essential for confirmed patients to prevent the spread of the disease to others and for healthcare workers to avoid getting the disease themselves. Informational posters can help improve PPE compliance among employees.

Properly Using PPE